History

DAG

ZACHEM

In the early 1960s, the Plant began testing experimental isocyanate, diene and polycarbonate installations. Studies were carried out for purposes of analysing the capacity for developing a polyurethane manufacturing complex. Over the next decade, the works invested in production lines and installations to manufacture and/or handle flexible polyurethane foams, brine electrolysis, phosgene, dinitrotoluene (DNT), toluene diamine (TDA), toluene diisocyanate (TDI), epichlorohydrin (ECH), and rigid foams and polyurethane foam (PUR) fittings for the automotive industry. The Chemical Plant manufacturing profile had been evolving over decades in reflection of market needs and the Polish political and economic situation. It was further affected by the investment slump bred by Poland’s economic troubles in the 20th century.

Produce of fundamental and key significance manufactured by the Plant in its final stage of operation included toluene diisocyanate (TDI), allyl chloride, epichlorohydrin (ECH), hydrochloric acid (HCl), sodium hydroxide (NaOH) i and sodium hypochlorite (NaClO). TDI is an organic chemical compound of the aromatic isocyanate group used in polyurethane synthesis. Allyl chloride is similarly used in organic synthesis for allyl group introduction purposes (CH2=CHCH2−), and in pharmaceuticals, dye, plastics, insecticide, and glycerine production. It is an organic chemical compound of the chlorinated olefin derivatives group.

At the “Zachem” Chemical Plant in Bydgoszcz, epichlorohydrin (ECH) was used in epoxy resin production, and to manufacture synthetic glycerol, elastomers, plasticisers, glycidyl ethers and esters, and water-resistant resins used in the paper industry. Epichlorohydrin was manufactured for the textiles-and-weaving industry, used in water-resistant paper production, and to produce an extensive selection of surfactant compounds, bactericides, insecticides, fungicides, pharmaceuticals, lubricant additives, corrosion inhibitors, compounds used in zinc electroplating, flame retardants, electric wiring insulation polymers and urethane-based compounds.

Such substances as hydrochloric acid, sodium hydroxide and sodium hypochlorite are inorganic group materials commonly used by the “Zachem” Chemical Plant in Bydgoszcz as core raw material.

Mass-scale produced goods include polyurethane foams. Compounds such as polyurethanes (PUR/PU) are products of addition polymerisation, multi-purpose isocyanates, amines and alcohols. Foams are the lead application of polyurethanes volume-wise. PU foams manufactured by the former “Zachem” S.A. Chemical Plant were used chiefly in the automotive industry, and in the furniture (upholstery and mattress foams), automotive (upholstery foams, rigid bumper foams, interior decoration components, shock absorbers), footwear and textile (foam-lined and thermal insulation fabrics) industries. Other uses include bath sponges, assorted insulation materials, sealing putty, adhesives and glues.

In years of its most dynamic development, “Zachem” employed over 7,000 people (the 1976 headcount reached 7,278), another 6,000 working at collaborating companies. The Chemical Plant occupied a site 484 hectares in area, with 120 km of roads with in-house bus connections and 70 km of railway tracks with an on-site railway stop: Bydgoszcz-Żółwin. Employee amenities included a kindergarten and primary school, young people also enrolled in vocational schools with a chemical technology focus. The “Zachem” site offered a staff canteen, outpatient clinic, small-size hospital and a centre of culture organising assorted meetings and competitions, such as the “Zachem” CEO’s Cup ballroom dancing competition. The “Zachem” S.A. Chemical Plant was obviously fitted with multiple and varied industrial infrastructure: a district heating plant, fire-fighting unit and – first and foremost – a chemical emergency response and first aid station.

The Bydgoszcz Chemik Sports Club was formed on January 30th 1976 with white, blue and red as club colours. Apart from a club stadium, Chemik owned a sports hall in the Bydgoszcz district of Wyżyny, and had a large group of loyal followers. Social benefits and staff infrastructure was equally extensive in “Zachem”’s glory years – suffice to mention the cinema, in-house Głos Zachem-u (Voice of Zachem) daily newspaper published in the years 1964-1989, in-house radio broadcast centre, printing house and staff quarters. “Zachem” employees could spend holidays at the Plant’s rest & recreation centre in Sopot (seaside) or spa in Ciechocinek.

Ciech

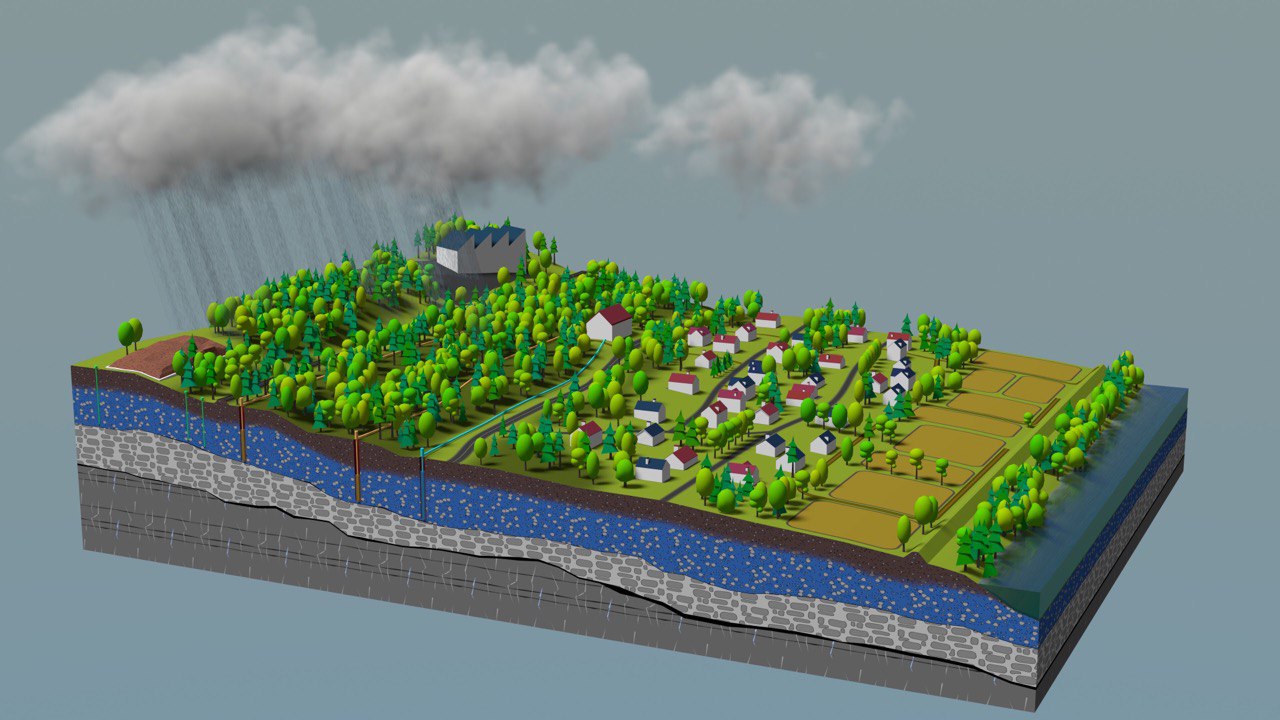

Nonetheless, successive Plant restructuring efforts did not save it from bankruptcy. In the final stage, from August 14th 2013 onwards, the “Zachem” Chemical Plant in Bydgoszcz operated as Infrastruktura Kapuściska S.A. owned by the Ciech S.A. Chemical Group. Four months later, organic and inorganic chemical compound manufacturing ceased altogether. The company focused on providing services in areas of infrastructure management and utilities access handling for businesses in the Infrastruktura Kapuściska neighbourhood. The company was declared bankrupt on March 14th 2014, all remaining property managed by a receiver who evaluated post-Chemical Plant assets at PLN 133 million. The property was put up for sale for PLN 108 million. Since nobody submitted a sales bid until July 8th 2014, the effort to sell “Zachem” assets (technological infrastructure, power transmission installations, real estate) piecemeal began. The site comprised an industrial water and sewage grid, waste landfills, and locations where assorted environmentally harmful substances collection continues until this day.

Did you know?:

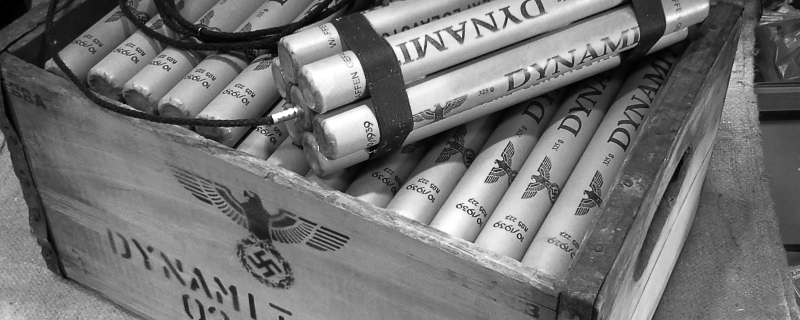

Did you know that 25 bags of TNT were lost en route from “Zachem” to the People’s Republic of China in 1967? Given that each bag weighed 40 kg on average, around a tonne of explosive TNT (trinitrotoluene) went missing. The Citizen’s Militia (contemporaneous police force) handled the case. Despite many efforts, it was never solved!

Did you know that on initiative of the “Solidarity” Independent Trade Union, a cross bearing the names of all employees who had lost their lives in accidents at work on the Plant’s site was erected in 1981? Despite resistance from authorities fearing “Solidarity”-incited manifestations, the monument was finally unveiled near the main entranceway to the works, on Wojska Polskiego Street.

Kids, did you know?:

Did you know that “Zachem”’s history can be traced back nearly 200 years to Alfred Nobel? He was the original founder of Nobel Prizes awarded for world-changing, outstanding scientific accomplishments!

Reference sources:

-

Exploseum – Military Technology Centre DAG Fabrik Bromberg

-

Leon Wyczółkowski Regional Museum in Bydgoszcz. EXPLOSEUM.

-

D. Pietrucin (2012) – Migration of Contaminants in the Anthropogenic Formation Aeration Zone on the Site of the Former Nitroglycerine Factory Dynamit-Aktien Gesellschaft (DAG) Fabrik Bromberg in Bydgoszcz.