INJECTION WELL COMPLEX IN THE REMEDIATION SYSTEM

The system of injection wells pumping waters into the aquifer is one of the main components of the remediation system designed to handle the plume of contaminated groundwaters and land linked to the “Zielona” waste landfill complex of the former “ZACHEM” Chemical Plant. At this stage, the main remediation measure involves the re-pumping of treated or pre-treated waters into Quaternary rock mass. This allows direct treatment of groundwater and soil plume pollution, combined with permanent hydraulic monitoring of the aquifer.

Pump-and-treat is a fairly common method of treating groundwater contaminated by substances dissolved, or residual in the non-aqueous phase. In the pump-and-treat process, contaminated groundwater is pumped directly from the aquifer. Groundwater is pumped from the well to a surface treatment contaminant removing system – or, occasionally, to a retention tank – until treatment begins. Pump-and-treat systems are also used to prevent contaminant plume migration. Pump-and-treat methods may involve a multiple well system to extract contaminated groundwater. The treatment system may comprise a single method, such as an active barrier based on activated carbon sorbent material or air stripping (bespoke groundwater method); it may also be a complex system using a number of different physical and chemical reactions.

Once surface treated, water is repumped beneath ground level. Pump-and-treat systems are an appropriate remediation process for early environmental treatment stages. Since the method efficiency declines with time, successive remediation stages – most frequently biological method-based – are implemented to sustain contamination residue treatment.

Groundwater is an extremely valuable deposit resource in Poland, requiring quantitative and qualitative protection, its efficiency equal to that applied to other domestic deposits. Capacity for self-renewal is groundwater’s unique property. It is to that end that the ongoing pump-and-treat-based remediation project involves the re-injection of treated or pre-treated water into the Quaternary aquifer, targeting sound management of water resources, primarily reduction of change to the groundwater flow regime. This process involves a system of four injection wells developed along an axis perpendicular to the centreline of the diagnosed contaminant plume spread. The process of re-injecting water into the rock mass requires a great deal of knowledge and experience in hydrogeological work, as it involves change to the hydraulic gradient, and to groundwater flow directions and velocity in the aquifer. All change is obviously well-planned and monitored, and – when combined – becomes a single remediation technology component.

The injection system is a set of hydrotechnical devices: individual wells. According to definition, their purpose is to deliver fluid to underground porous geological formations. These formations are found at assorted depth levels: a significant several hundred metres below ground level right up to shallow ground. Injected (pumped) fluids can include water, wastewater, brine or water mixed with chemicals. The design of each individual injection well depends on the type and depth of the fluid to be injected. In theory, for example, wells injecting hazardous waste or carbon dioxide (CO2) to deep and isolated formations will be intricate in design. These wells would be designed to secure multiple protective shield and cement layers. Shallow well design, on the other hand, is usually relatively simple.

Injection wells have a number of purposes, most frequently including the following: (1) CO2 storage, (2) waste utilisation, (3) increased crude oil production, (4) mining, (5) preventing saltwater intrusion, (6) pumping water to feed the aquifer.

Along your educational tour, you can learn more about how injection well SI3 works; the well is located in the impact zone of the “Zielona” waste landfill complex, a component of the remediation system developed as part of the project. Well SI3 was drilled to a depth of 23 metres. In well SI3, water is injected under pressure into the aquifer at a maximum capacity of 22 m3/h, the cone of impression at 2.1 metres.

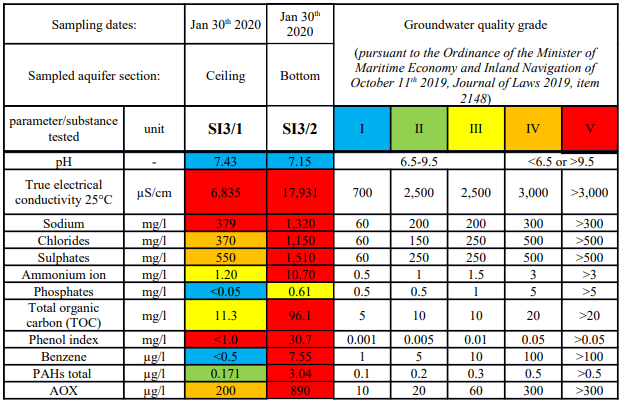

The table below shows test results for groundwater sampled from well S13 in 2020. Tests preceded the start of target remediation works, groundwater samples collected and tested according to an accredited procedure after the borehole had been pumped:

Clarification: grade I – blue, grade II – green, grade III – yellow, grade IV – orange, grade V – red.

Did you know?:

The funnel (or cone) of impression develops when water is injected through the well to the bespoke aquifer. The underground water table impression is the accrual or rise of water levels in comparison with the original level. Depression is the opposite of impression: also funnel-shaped, it is a decline of the water table in the borehole.

Kids, did you know?:

Skilful use of injection wells requires great aquifer control! Water has to be injected at a slow yet constant rate. Otherwise, if water is discharged forcefully, the outcome can resemble pressing an obstructed syringe full of water. Water will spill and leak around the plunger!

Reference sources:

-

D. Pierri, A. Postawa, M. Czop (2019) – Significance of pump-and-treat method in remediation process of highly contaminated ground and water environment; based on example of former ‘ZACHEM’ Chemical Plant (Bydgoszcz City, northern Poland).